Steel Production: A Dirty Industry in Need of a Green Revolution

Steel, a backbone of modern life, is used in skyscrapers, cars, airplanes, bridges, and more. Unfortunately, steelmaking is an extremely dirty process, accounting for around 7 to 9 percent of humanity’s greenhouse gas emissions worldwide. The most common way it’s produced involves mining iron ore, reducing it in a blast furnace through the addition of coal, and then using an oxygen furnace to burn off excess carbon and other impurities.

Steel production is a dirty process

Steel production is a dirty process

Now, Boston Metal is seeking to clean up the steelmaking industry using an electrochemical process called molten oxide electrolysis (MOE), which eliminates many steps in steelmaking and releases oxygen as its sole byproduct. This innovative approach has the potential to transform the industry and significantly reduce greenhouse gas emissions.

Boston Metal is leading the way in green steel production

The company, founded by MIT Professor Emeritus Donald Sadoway, Professor Antoine Allanore, and James Yurko PhD ‘01, is already using MOE to recover high-value metals from mining waste at its Brazilian subsidiary, Boston Metal do Brasil. This work is helping Boston Metal’s team deploy its technology at commercial scale and establish key partnerships with mining operators. It has also built a prototype MOE reactor to produce green steel at its headquarters in Woburn, Massachusetts.

MOE reactor at Boston Metal headquarters

MOE reactor at Boston Metal headquarters

And despite its name, Boston Metal has global ambitions. The company has raised more than $370 million to date from organizations across Europe, Asia, the Americas, and the Middle East, and its leaders expect to scale up rapidly to transform steel production in every corner of the world.

Boston Metal’s global ambitions

Boston Metal’s global ambitions

In a world where climate change is a pressing concern, it’s heartening to see companies like Boston Metal taking bold steps to reduce emissions and promote sustainability. As Guillaume Lambotte, Boston Metal Chief Scientist and former MIT postdoc, says, “There’s a worldwide recognition that we need to act rapidly, and that’s going to happen through technology solutions like this that can help us move away from incumbent technologies.”

Guillaume Lambotte, Boston Metal Chief Scientist

Guillaume Lambotte, Boston Metal Chief Scientist

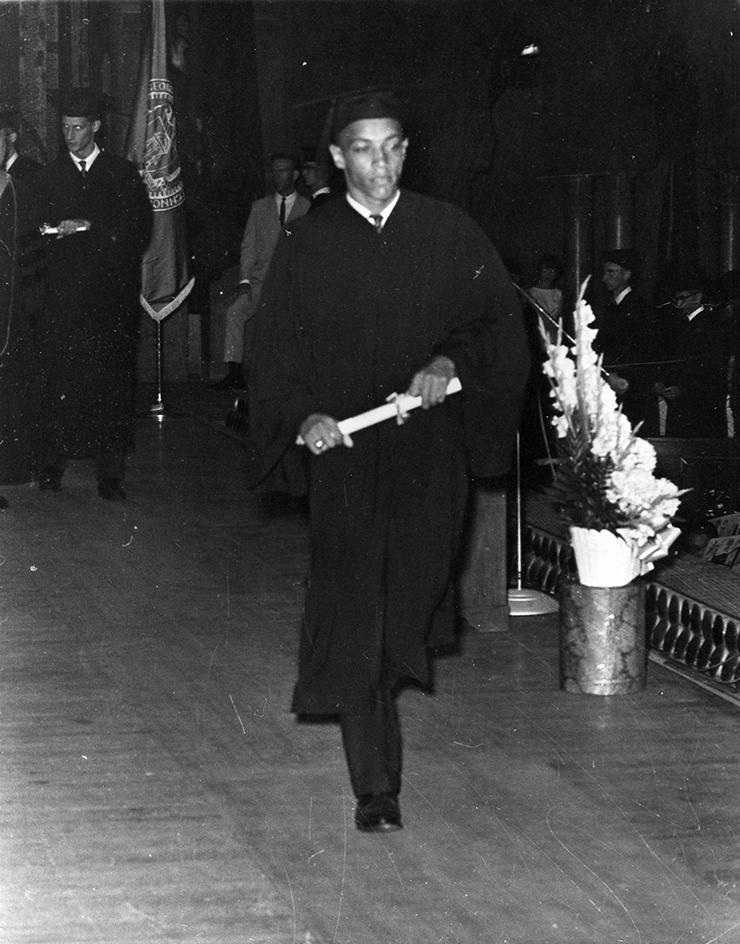

In other news, Ronald Yancey, the first Black graduate of Georgia Tech, recently presented a degree from the school to his granddaughter, marking a significant milestone in their family’s history.

Ronald Yancey and his granddaughter

Ronald Yancey and his granddaughter

Meanwhile, the world of social media continues to grapple with issues of misinformation, scams, and fake profiles. It’s a reminder that even as we celebrate innovation and progress, we must also remain vigilant about the potential pitfalls of technology.

The darker side of social media

The darker side of social media

In conclusion, the story of Boston Metal serves as a beacon of hope in the fight against climate change. As we look to the future, it’s heartening to see companies and individuals working together to create a more sustainable world.

A more sustainable future

A more sustainable future