The Sustainable Impact of Antimicrobial Technology

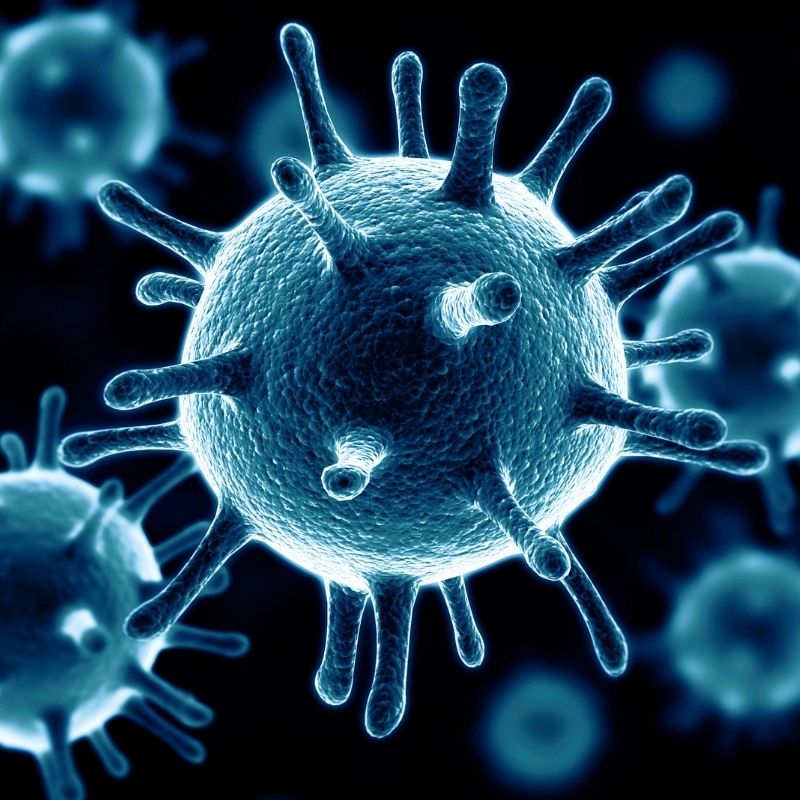

Healthcare-associated infections (HCAIs) pose a serious and growing threat, putting staff and patients at risk and incurring significant costs. In the UK, for instance, 653,000 HCAIs were reported among 13.8 million adult in-patients in the NHS from 2016-2017, of which 22,800 patients died as a direct consequence.

The alarming rise of HCAIs

The alarming rise of HCAIs

The main sources of microorganisms in hospitals are patients’ own microbiota, and the hands of healthcare workers, patients, and visitors. High-touch plastic surfaces, such as medical weighing scales, clinical workstations, hospital carts, dispensing cabinets, and even chairs, can contribute to the chain of microbial transmission, by acting as reservoirs on which transferred bacteria can survive and multiply.

“Policies that implement regimented hand washing and thorough, frequent disinfection of all surfaces are crucial to help prevent unwanted bacterial growth, but compliance tends to be suboptimal, and surfaces are quickly re-contaminated by dirty hands.”

Tackling an Unseen Problem

Bacterial growth on plastic products in a medical setting can also cause staining, discolouration, structural damage, or even odours, creating an unpleasant environment for patients and healthcare professionals. Deterioration causes items to be thrown away prematurely, adding to the environmental burden of the healthcare sector and incurring extra costs in terms of replacement goods.

The unseen consequences of bacterial growth

The unseen consequences of bacterial growth

Healthcare providers are therefore seeking out new ways to combat these issues, including implementing proactive measures to maintain a clean medical environment and reduce the volume of waste generated by the industry.

Regular cleaning of high-touch surfaces is crucial to protect items from the growth of potentially harmful bacteria, however, standard disinfectants retain limited residual activity after application. Built-in antimicrobial technologies can be used in conjunction with regular cleaning practices to prevent the proliferation of damaging bacteria on plastic goods in healthcare settings, preserving their usability.

The power of antimicrobial technology

The power of antimicrobial technology

These antimicrobial formulations can be seamlessly engineered into polymer products during manufacture using standard coating processes, such as injection moulding and extrusion, and into coatings and paints via spraying, roll-to-roll, or dip application methods. They therefore become an integral part of the molecular structure of the polymer, and work around the clock to help inhibit the growth of bacteria without the risk of washing off or wearing away.

A Proactive Approach to Microbial Control

Sustainability initiatives for antimicrobial technologies have stressed the importance of features like biocompatibility and biostability in recent years, making water-based antimicrobial coatings that contain fewer volatile organic compounds increasingly appealing to manufacturers.

Sustainable solutions for a greener future

Sustainable solutions for a greener future

These novel coatings, such as LapisShield by Microban, provide long-lasting protection for water-based coatings, and can be applied to a broad spectrum of substrates. The active ingredient in LapisShield works by disrupting the bacteria’s internal enzymes to block metabolic pathways and create an inhospitable environment that interrupts reproduction. Additionally, the technology is free from heavy metals, and is registered with the U.S. Environmental Protection Agency and the EU Biocidal Products Regulation, making sustainable antimicrobial water-based coatings more accessible to healthcare equipment manufacturers around the world.

A Cleaner, Greener Outlook

Incorporating antimicrobial additives into plastic clinical surfaces and products at the point of manufacture is an integral part of ongoing plans to enhance cleanliness in healthcare environments. In fact, the healthcare segment accounted for 26% of the overall global revenue share of the antimicrobial additives market in 2021, and is expected to experience the fastest annual growth rate in the years leading up to 2030.

A cleaner, greener future for healthcare

A cleaner, greener future for healthcare

New antimicrobial technologies for polymers – which are easy to incorporate, aesthetically pleasing, highly functional, and free from heavy metals – hold enormous potential for transforming the definition of clean in healthcare and provide much-needed peace of mind for staff and patients alike.

On top of this, built-in antimicrobials are valuable tools for promoting sustainability and building a circular economy in the medical sector, with technologies for polymers, solvent-based coatings, and paints paving the way for this industry-wide green transition.